UNIMAT Secondary Level

160141EDUB

Versatile, Modular, and Practice-Oriented – For Schools and Technical Education

The UNIMAT Secondary I is the advanced version of the successful UNIMAT Primary School Set. Specifically designed for students aged 12 and up, it is ideal for use in lower secondary education.

In addition to traditional technology classes, it’s perfectly suited for creative workshops, after-school programs, and project-based full-day learning environments.

The set provides a hands-on introduction to technical education without compromising on child-friendly safety or modular flexibility.

🧰 Expanded Capabilities for Wood, Metal, and Materials

At the heart of this set is the combination of proven woodworking tools with extended capabilities for working with metal and other materials.

Basic Equipment (Woodworking):

- Lathe

- Jigsaw

- Sanding Machine

- Hand Drill

Extended Equipment (Secondary Level & Technical Education):

- Metal Lathe

- Horizontal Milling Machine

- Drill Press

- Vertical Milling Machine

This variety not only enables the realization of more complex projects but also introduces students to industrial manufacturing principles in an age-appropriate and accessible way.

🧠 Educational and Technical Value

The UNIMAT Secondary I provides a practical introduction to technical education while fostering both creative and analytical skills.

Students will learn:

- Safe handling of tools and materials

- Planning and implementation of technical projects

- Basic manufacturing techniques in wood and metal

- Responsible behavior in a workshop environment

Thanks to its modular structure, the system can be adapted to different age groups, class sizes, and levels of prior knowledge. The machines are assembled step by step, combined, and expanded—encouraging a deep understanding of technical concepts.

🏫 Flexible Use – in the Classroom and Beyond

The set is suitable for a wide range of school and extracurricular applications:

- Technology and craft classes in lower secondary school

- Full-day school projects and open workshops

- Technology clubs or maker projects

- Career orientation and vocational preparation

Whether in regular lessons, project-based learning, or as part of a STEM enrichment program—UNIMAT Secondary I fits wherever creative work meets technical depth.

Safety first!

The UNIMAT 1 Secondary expands on the UNIMAT 1 Primary School Set, offering a versatile, safe, and practice-oriented system for technical education.

The woodworking machines – including the woodturning lathe, jigsaw, sanding machine, and hand drill – are safely usable from the age of 8. They allow students to gain their first practical experience with materials while developing fundamental craftsmanship skills.

For more advanced technical applications from the age of 12, the set includes additional machines such as the metal lathe, horizontal milling machine, and drill press (vertical milling machine). These expanded functions enable more complex projects and provide deeper insights into metal and material processing.

The entire UNIMAT system is specifically designed for educational use, ensuring safe and age-appropriate operation. Thanks to its modular design, it can be flexibly adapted to different age groups and skill levels, enabling a comprehensive technical education – from basic manual skills to advanced manufacturing processes.

Machine applications

Jig Saw

The powerful jigsaw can be used with plywood, solid wood (up to 7 mm), balsa wood (20 mm), plastics and thin metal sheets. No annoying opening and clamping of the jigsaw blade when cutting windows and notches

Sanding Machine

The stationary rotating sanding disc provides the final touch to your work pieces and can sharpen your tools: from scissors to carving knives, chisels, gouges, etc. It can also be used as a hand-sander for hard-to-reach places.

Wood Lathe

The smallest lathe in the world creates elaborate pieces of turned wood. The small machine achieves an outstanding result with a distance between centers of 135 mm (extendable) and up to 50 mm diameter, while still being childproof. Candle holders, scale masts, gun barrels, doll house furniture ... all easily done.

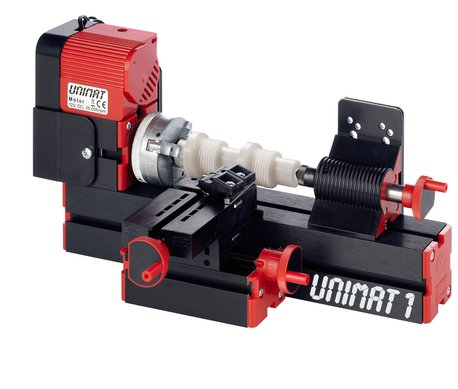

Lathe

The longitudinal and cross slides with precision-scaled handwheels enable highly accurate machining. Designed like a professional lathe, the UNIMAT 1 allows for the precise manufacturing of axles, rims, cannons, and other turned parts from soft and non-ferrous metals.

Technical specifications:

- Distance between centers: 135 mm (expandable)

- Center height: 25 mm

Horizontal mill

Ideal for architectural models, key and slot joints, and precision work. The collets with a clamping range of 1 to 6 mm ensure high concentric accuracy of the milling bit. The tiltable slides allow for precise milling at various angles, enabling versatile machining options.

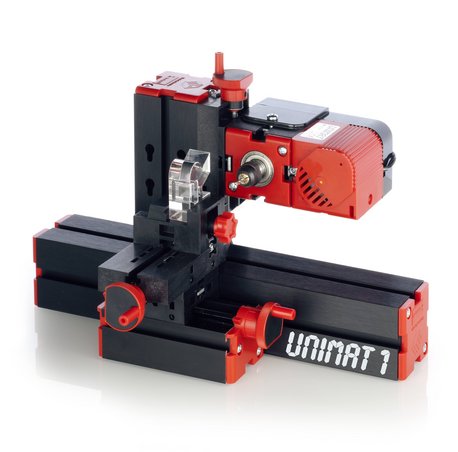

Drill press

Precise Drilling at Any Angle

The machining center enables highly accurate movements along the X, Y, and Z axes. Three precision-guided, swiveling slides allow for versatile, three-dimensional machining.

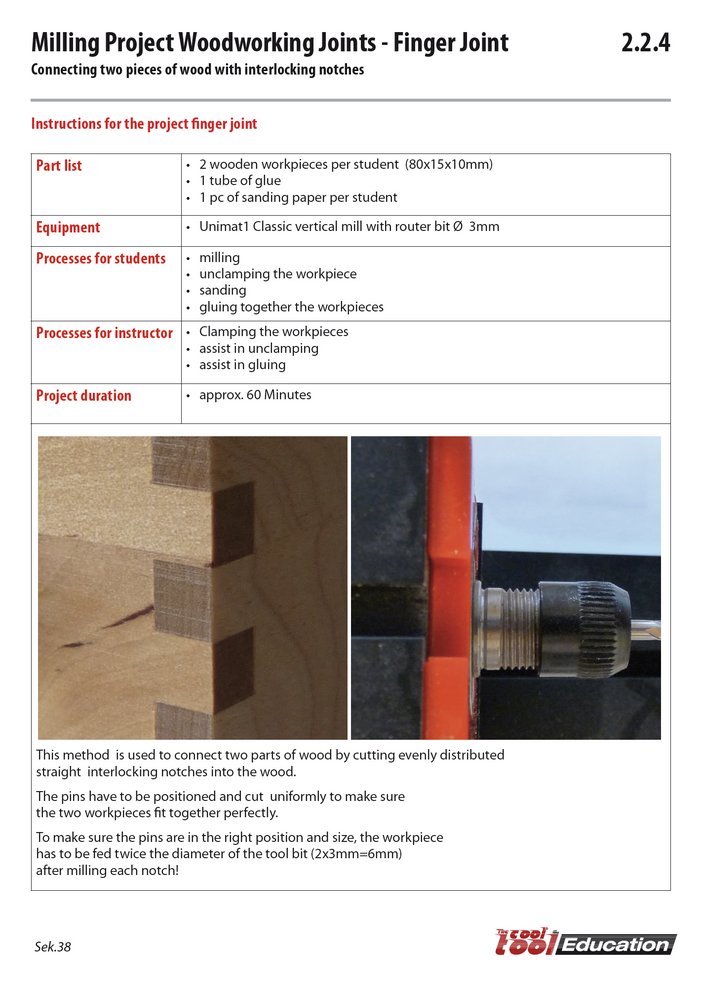

Machine Variant: Vertical Milling Machine

With the included HSS milling cutter, the drill can be easily converted into a vertical milling machine. Additionally, standard tools with a shank diameter of up to 6 mm can be clamped securely.

Woodturning Variants

Faceplate Turning: The work piece is clamped on only one side using the faceplate.

Miniature Lathe: Tiny rods of wood or soft metal (up to 6 mm Ø) can be clamped with collets

Handheld Drill

For drill and engraving bits from 1 to 6 mm. Perfect for drilling at inaccessible spots and engraving.

Technical Data

Motor: 20.000 rpm, 12 VDC

Headstock: M12x1, 8 mm hole through spindle

Gear ratio: 1:5 (4,000 rpm)

Tailstock: M12x1, 15 mm quill travel

Adaptor: 110-240V/50-60Hz,12V DC, 2A

Introduction to materials science with UNIMAT Secondary

The UNIMAT set for secondary education enables the precise machining of a wide range of materials. In addition to wood – a proven and sustainable material – it allows for the efficient processing of soft metals, plastics, stone, and other materials. The expanded functions of the lathe and milling machine offer a broad spectrum of machining options, opening up diverse applications in technical education.

Through hands-on work with UNIMAT, students acquire comprehensive knowledge of material processing and deepen their understanding of technical processes. They further develop their craftsmanship skills while also improving their fine motor skills, concentration, and problem-solving abilities.

Integrating UNIMAT into the classroom provides a practical introduction to technology, preparing students for advanced technical training or careers. At the same time, working with real, physical workpieces offers a valuable alternative to an increasingly digital learning environment and fosters a deeper understanding of mechanical manufacturing processes.

UNIMAT 1 Secondary

A Complete Set for Technical Education

Includes all components for assembling the following machines:

- 3-axis milling machine (vertical or horizontal)

- Metal lathe

- Drill press

- Woodturning lathe

- Jigsaw

- Sanding machine

- Hand drill or hand grinder

Also included:

- Safety transformer 14V/100-240V

- Woodturning tools

- Various hand tools & drill bits

- Lathe cutting tools

- Sandpaper

- Live center

- Mounting brackets & fixing plates

- Drilling table

PLUS EDU Upgrade Package:

- Tool sharpening device

- Metal lathe tool rest

- Safety goggles

- 10 jigsaw blades

- Wooden baseplate with non-slip pad

- 2 micro clamps

- Metal collets