UNIMAT MetalLine - Technical Education

160200EDUB

The UNIMAT MetalLine Set – Advanced Technical Training with Metal

The UNIMAT MetalLine Set was specifically developed for metalworking in technical education.

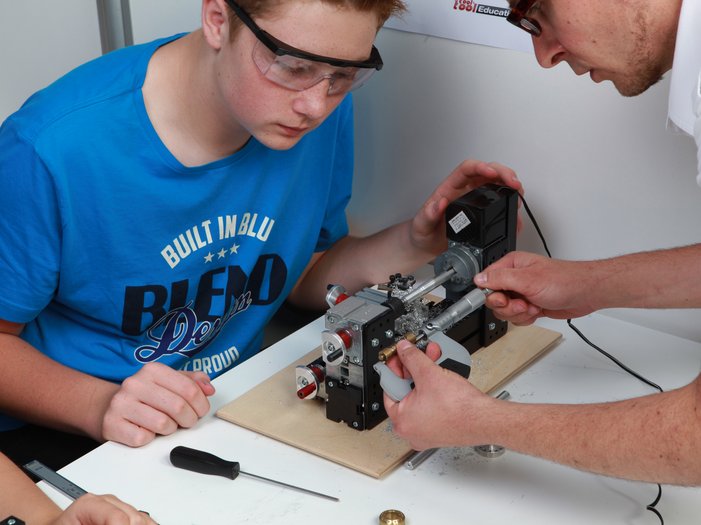

It is designed for students aged 12 and older and is ideal for use in technology classes, training workshops, and early vocational orientation.

The focus is on precise production of technical workpieces using high-quality machines – a skill that is essential both in the classroom and in practical training.

⚙️ High-Quality Engineering for Demanding Projects

The MetalLine machines offer a quality typically found only in professional environments.

The system impresses with outstanding stability and enables fine adjustments during operation.

Thanks to its solid construction and precise components, tolerances under 0.1 mm can be reliably maintained – a crucial advantage wherever precision is required.

A key feature: the machines are equipped with metal handwheels and an adjustable vernier scale, allowing precise control of machining parameters – perfect for educational goals in metalworking, mechanical engineering, and manufacturing technology.

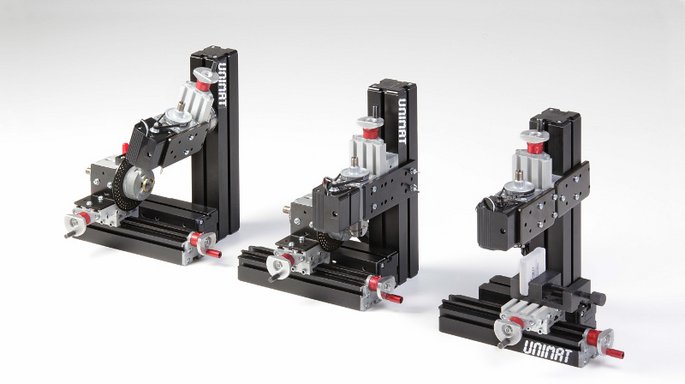

🔄 Modular Design – Versatile Applications

Like all UNIMAT systems, the MetalLine set is based on a modular machine structure.

Core machines such as the lathe, mill, and drill press can be flexibly reconfigured through quick assembly changes.

This allows the creation of complex workpieces across multiple production steps without the need for a full industrial machine park – lowering barriers to entry while enhancing understanding of manufacturing processes.

🧰 Learning Objectives & Hands-On Skills

The MetalLine set supports both basic and advanced metalworking tasks. It enables the creation of technically demanding projects, such as:

- Precisely turning cones

- Milling gears

- Drilling, grinding, and cutting non-ferrous and soft metals

This not only promotes technical understanding but also fosters manual precision and patience – key competencies for all areas of vocational training.

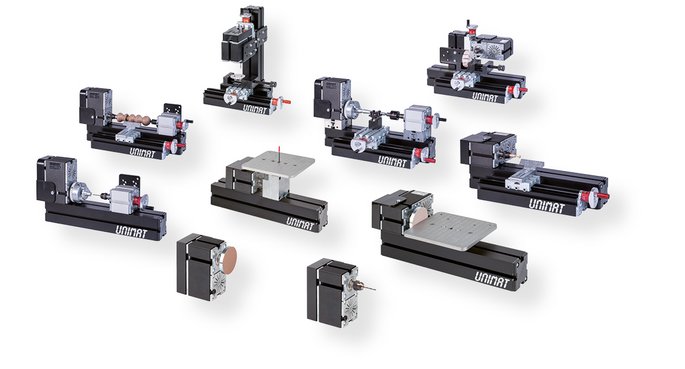

Machine variations

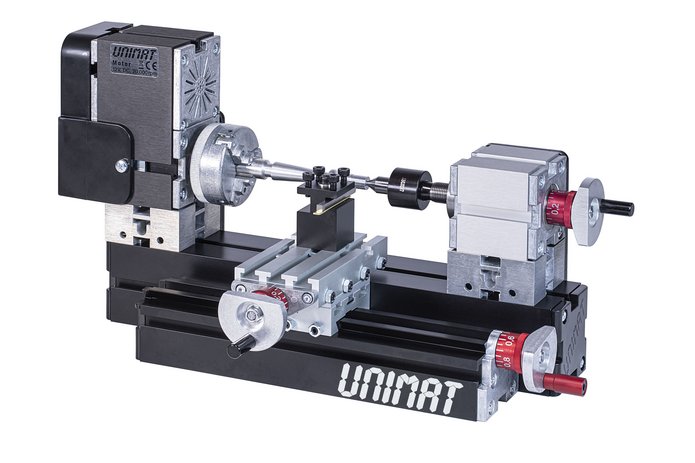

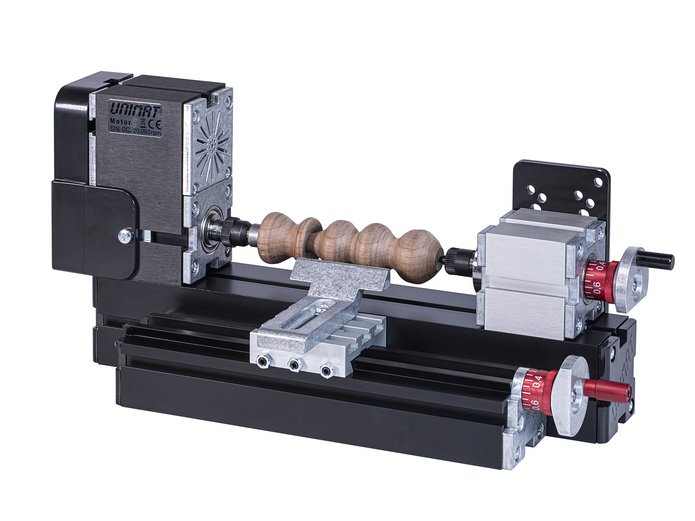

Metal lathe

With a center height of 50 mm, a center distance of 90 mm (expandable), and a multiple tool holder, aluminum, copper, brass, and other metals can be machined. The 3-jaw chuck allows workpieces up to ø 56 mm (65 mm with external clamping) to be securely fixed.

Travel distance: Z-axis 145 mm, X-axis 32 mm.

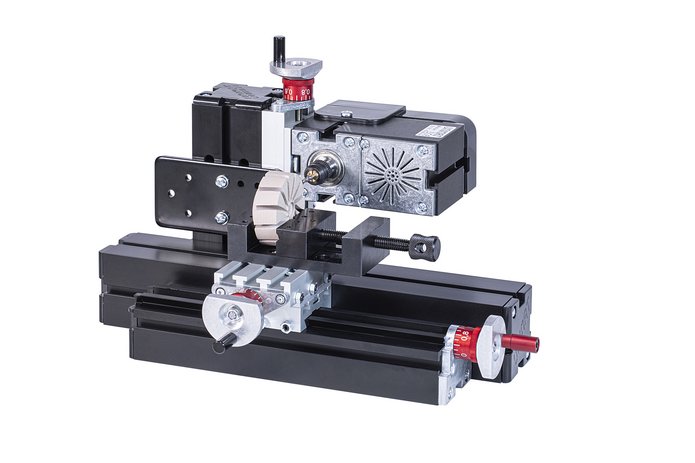

Horizontal mill

Using 3 slides allows for a wide range of milling tasks on different planes. Travel: X-axis 145 mm, Y- and Z-axis 32 mm (optionally expandable). Collets with a clamping range from 1 to 6 mm.

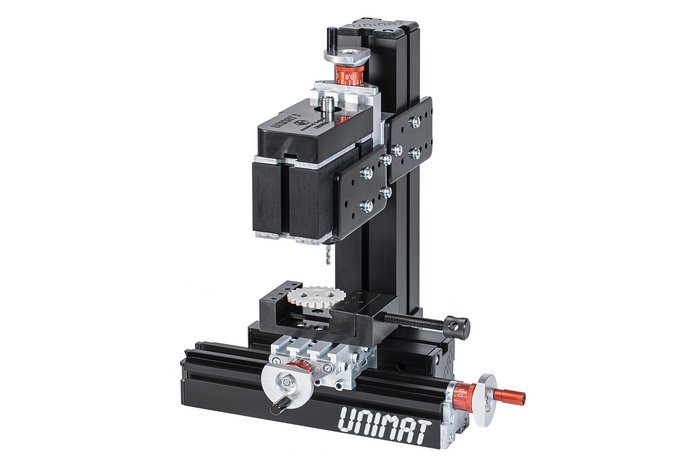

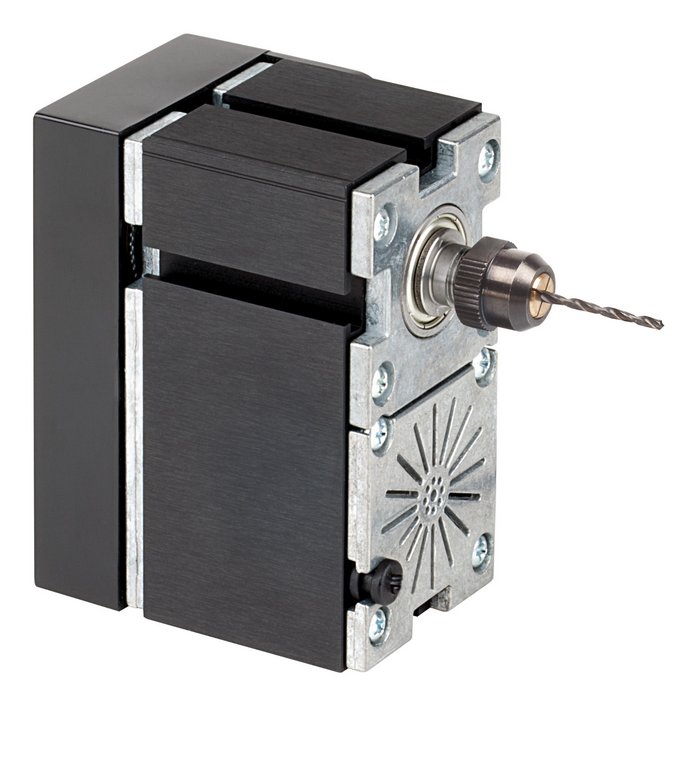

Vertical mill / drill press

The machining center allows for precise drilling at any angle, featuring movement along the X, Y, and Z axes. It includes three guided, pivotable slides for three-dimensional work.

In its Vertical Mill variant, the drill can be transformed into a vertical mill using the included HSS milling cutter. Standard tools up to 6mm can be clamped, enhancing its versatility for different tasks.

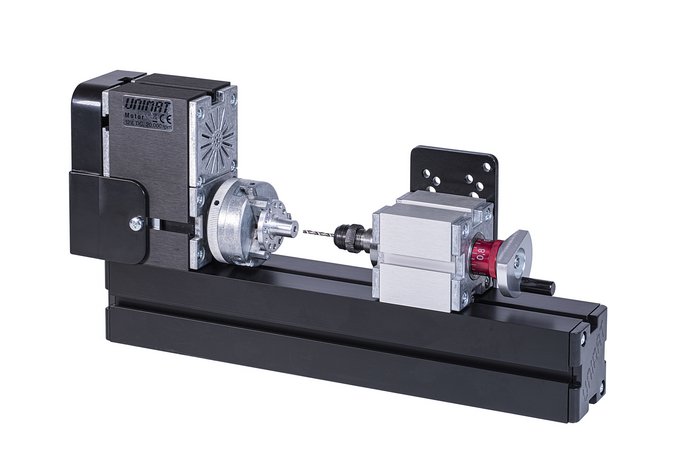

Center Drilling

With the precise collets, tool bits from 1 to 6 mm can be inserted into the head-spindle. The tailstock quill allows for a precise travel of 30 mm. The hand wheel with 0.05 mm scale guarantees perfect drilling results and exact depth-control.

Jig saw

The child-safe and powerful jigsaw allows for easy and quick sawing tasks. Its short stroke ensures that there's no risk of injury.

Fine work, similar to using a scroll saw, becomes quicker and more enjoyable.

The saw is suitable for plywood, solid wood up to 7mm, and balsa wood up to 20mm, working particularly well with 4mm poplar plywood.

Additionally, it eliminates the hassle of constantly having to remove and reinsert the jigsaw blade for cutting openings.

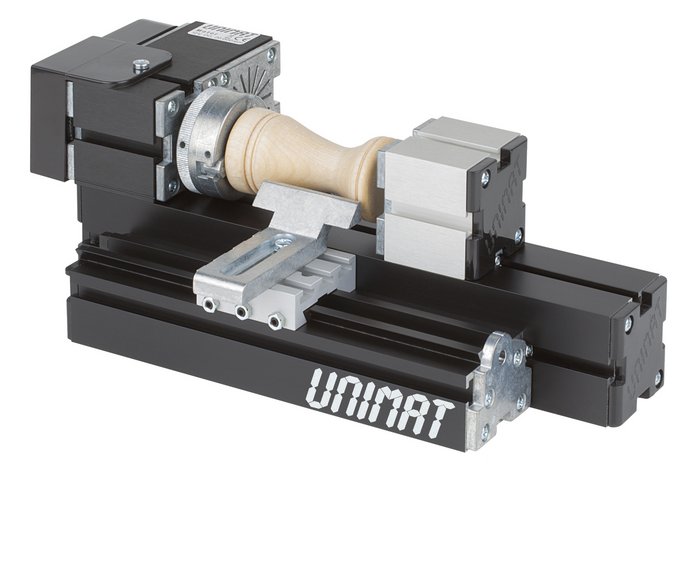

Wood lathe

With the safe lathe, students from the age of 8 can create great wood projects by themselves, using various types of wood.

The machine is completely child-safe and automatically stops under excessive strain.

Creative projects can be realized while also imparting technical understanding using the UNIMAT 1 lathe.

It's suitable for woods up to 50mm in diameter and 135mm in span (expandable).

Sanding machine

Safe sanding is ideal for giving your own workpieces the final touch or easily sharpening your own tools.

Hand drill

The drill allows for child-safe drilling in wood. The vibration of the drill bit ensures safety while still enabling the drilling of small holes.

Wood lathe variations

Faceplate Turning: The work piece is clamped on only one side using the faceplate.

Miniature Lathe: Tiny rods of wood or soft metal (up to 6 mm Ø) can be clamped with collets.

EDU-Upgrade Technics 2 (160200EDU2)

Addition to Unimat ML Technics (160200EDUB):

second headstock, second motor, dividing attachment, rotary table, gear cutting head, fly cutter, 4 pcs. milling tool set, 5-pcs. HSS turning steel set, 330mm machine bed + 2 connection pieces. To setup a second machine or machine upgrades like:

• gear cutter

• surface mill

• 5-axes mill

EDU-Upgrade Technics 3 Power (160200 EDU3)

Addition to Unimat ML Technics (160200EDUB).

NOT childsafe, only under supervision or for vocational training.

Powermotor, reduction set for powermotor, safety adaptor with junction box, circular saw with saw blade, precision milling attachment, professional woodturning attachment, 460mm machine bed with 2 connectors. To setup a second machine or machine upgrades like:

• circular saw • power jigsaw • router

• big woodturning lathe • power mill

Curriculum examples:

Curriculum example Technics I:

German state Mecklenburg-Vorpommern, for technical education, levels 7-10. S. 23. : "General architecture of machinery, devices; ...block diagram and facilities; ... cogwheel gearing mechanism (symbolic illustrations, models; experiment transmit, allocate reps. deflect rotating movement; change direction and rotational speed)"

Curriculum example Technics II:

German state Saarbrücken, Technology/Technical Mathematics Technical Communication Vocational Basic Education Vocational School - Subject Area Technique Upper Classes Subject Area TM1- Machining "Structure and principle of operation of Milling machines ... Outside and inside turning, lengthwise and crosswise turning with and without feeding ... centering, drilling"

Unimat ML Technics Set (160200EDUB)

Includes all parts in all-metal construction to build one out of these machines:

Modular setup for:

• Lathe

• Horizontal milling machine

• Vertical drilling/milling machine

• Wood lathe

• Centering drill

• Jigsaw

• Sanding machine

• Hand drill/grinder

Electrics & drive:

• 14 V safety transformer

Clamping & fixing accessories:

• Precision collets

• Mounting plates

• Mounting brackets

• Steel vise

Turning & sanding:

• Precision live centers

• Tool grinding fixture

• Woodworking set

• 10 jigsaw blades

Basic equipment:

• Wooden base plate with anti-slip

• 2 micro clamps

• Various tools

• Safety goggles

Miscellaneous:

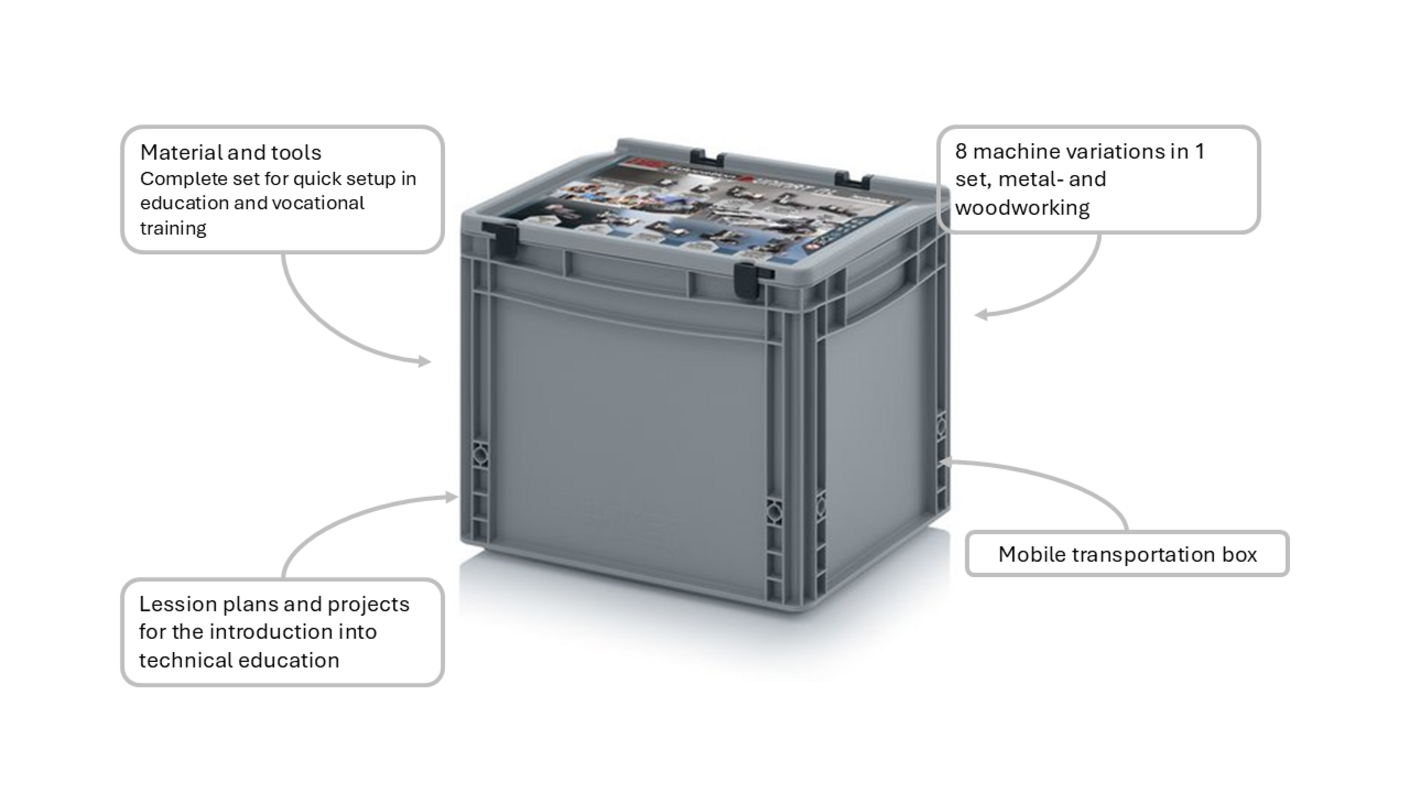

• Storage box

• Didactic teaching material

![[Translate to English:] Klassenraum mit UNIMAT MetalLine](/fileadmin/_processed_/5/5/csm_Schule_ML_efed4a77e0.jpg)