TCT Control

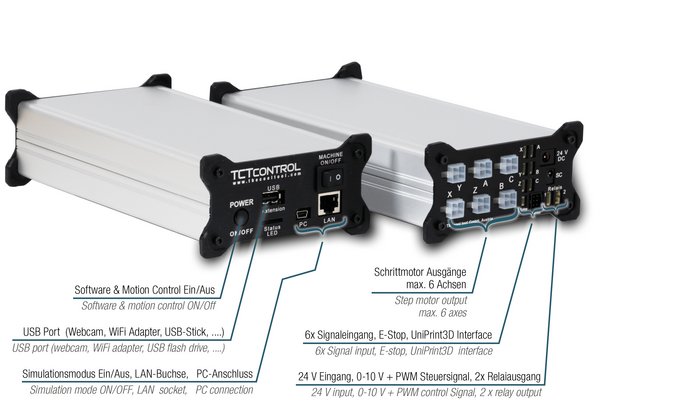

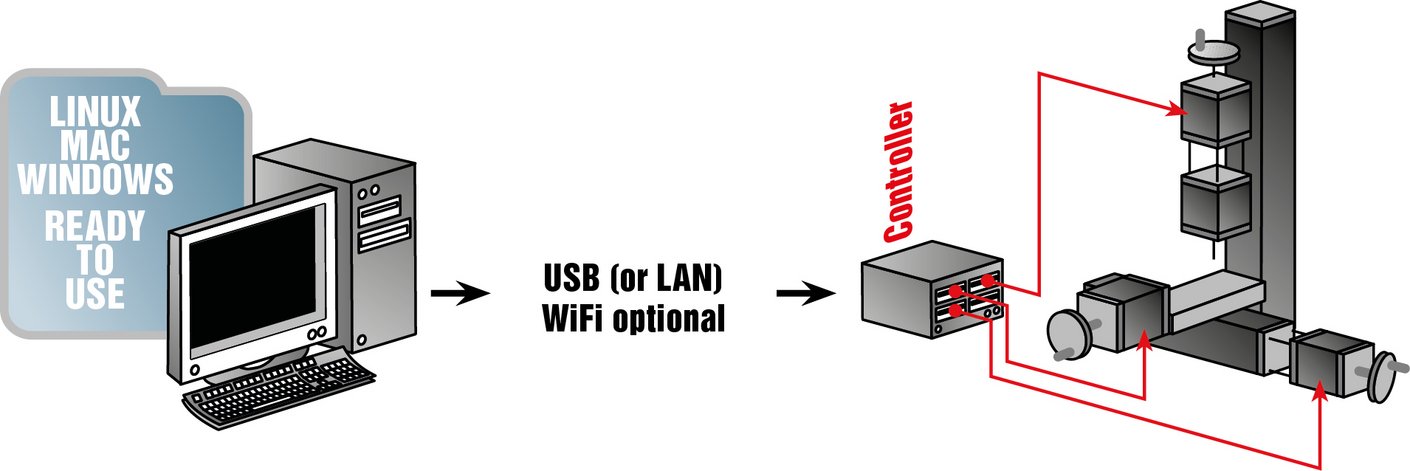

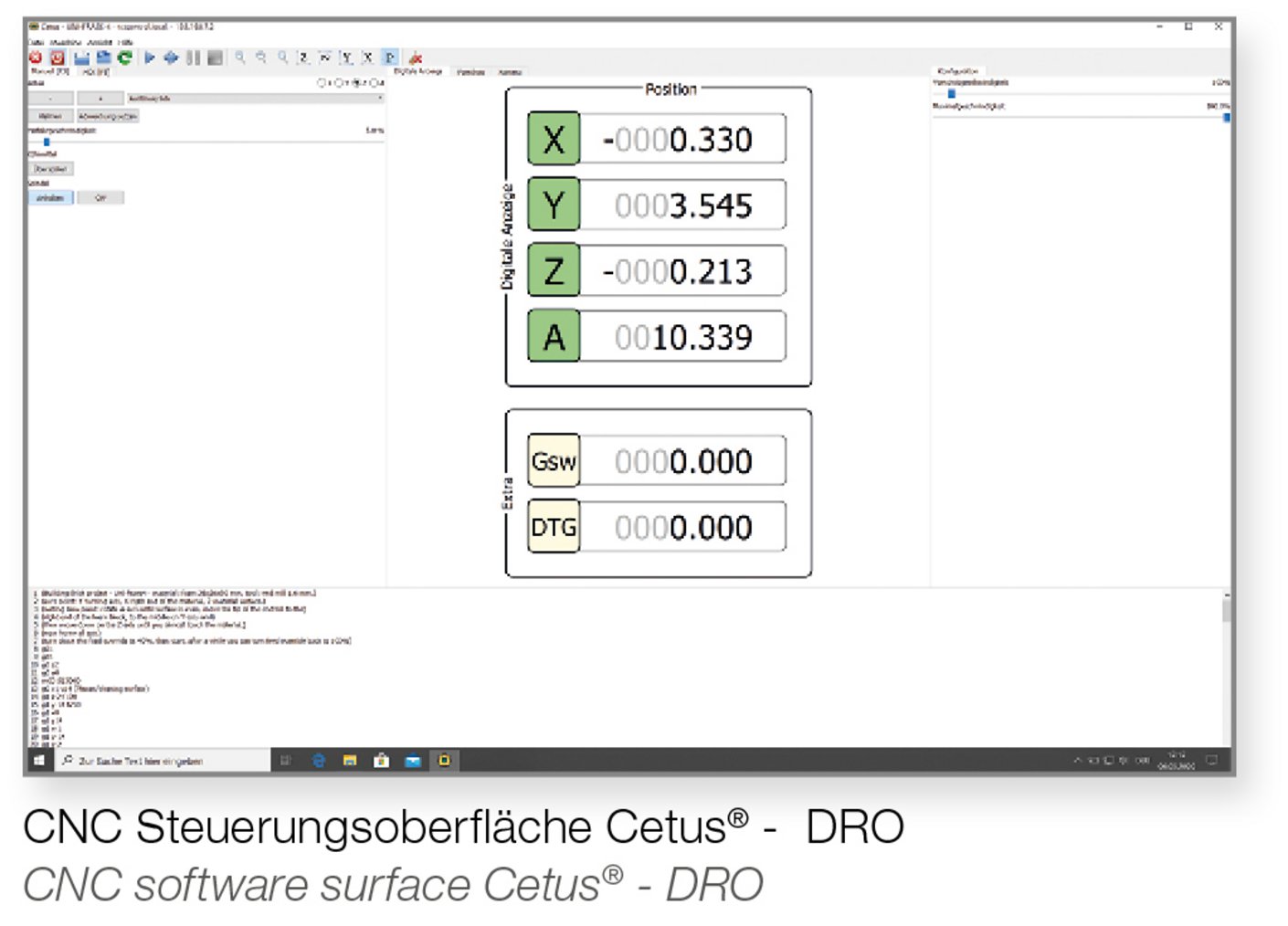

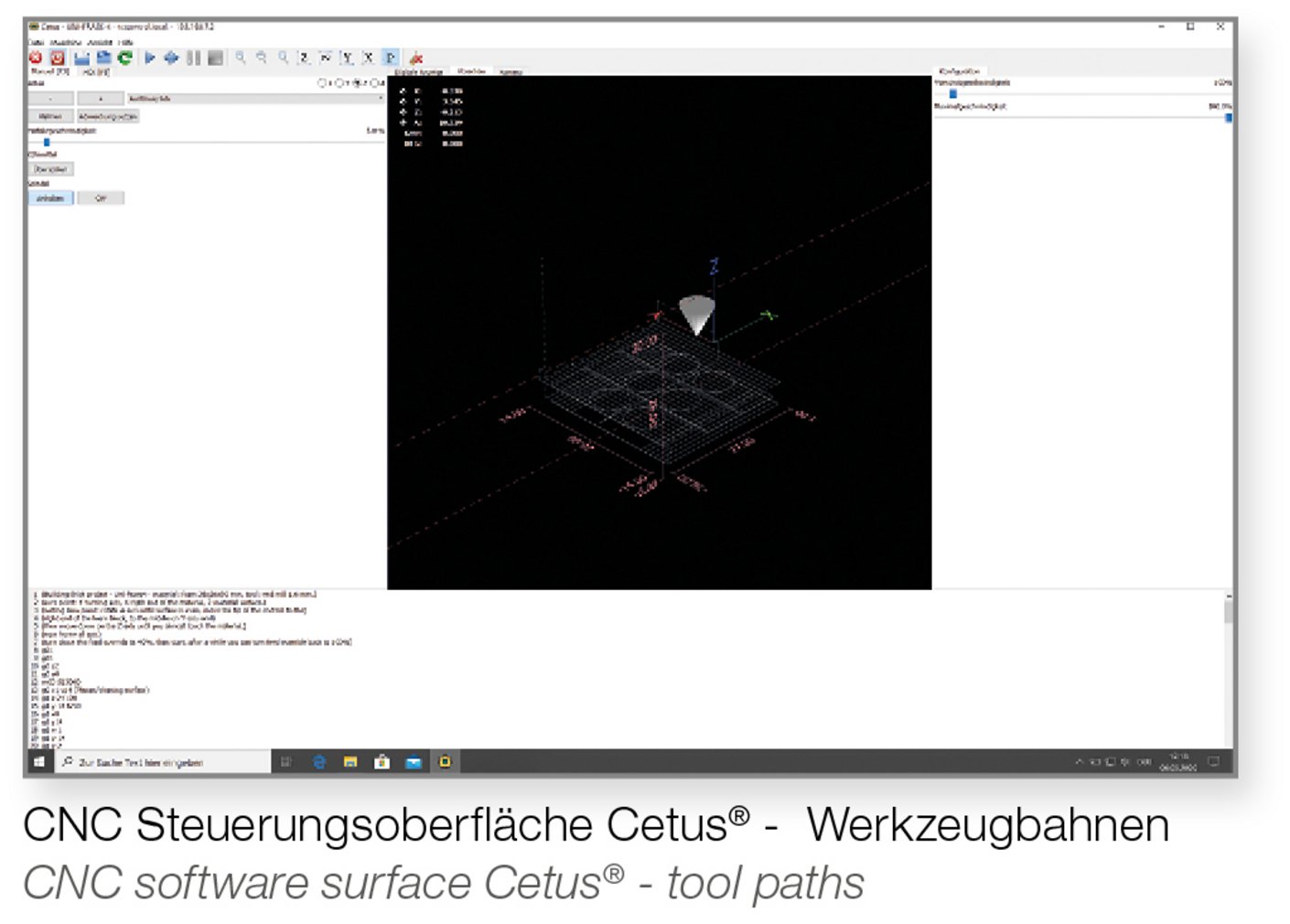

The TCTControl® stepper motor control unit is available in both 4-axis and 6-axis versions. It can control stepper motors with up to 2 A per phase. The software preinstalled on the TCTControl allows for loading, editing, and executing ISO G-code files (RS-274, DIN 66025).

It also includes:

- a toolpath simulation mode,

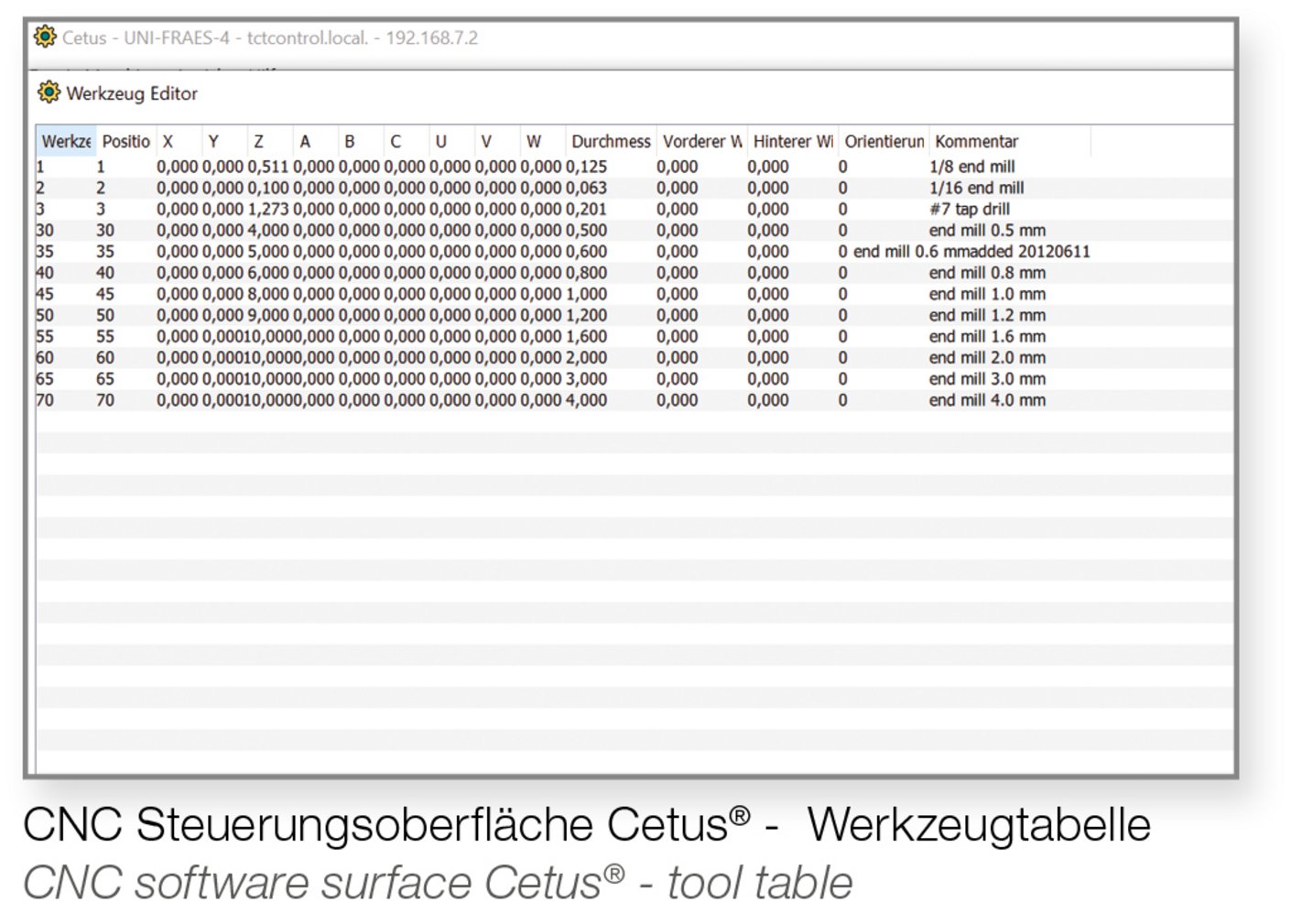

- an easily editable tool table,

- and many other features.

A user manual and training guide for an introduction to CNC and G-code programming are included.

UNIMAT CNC FAQs

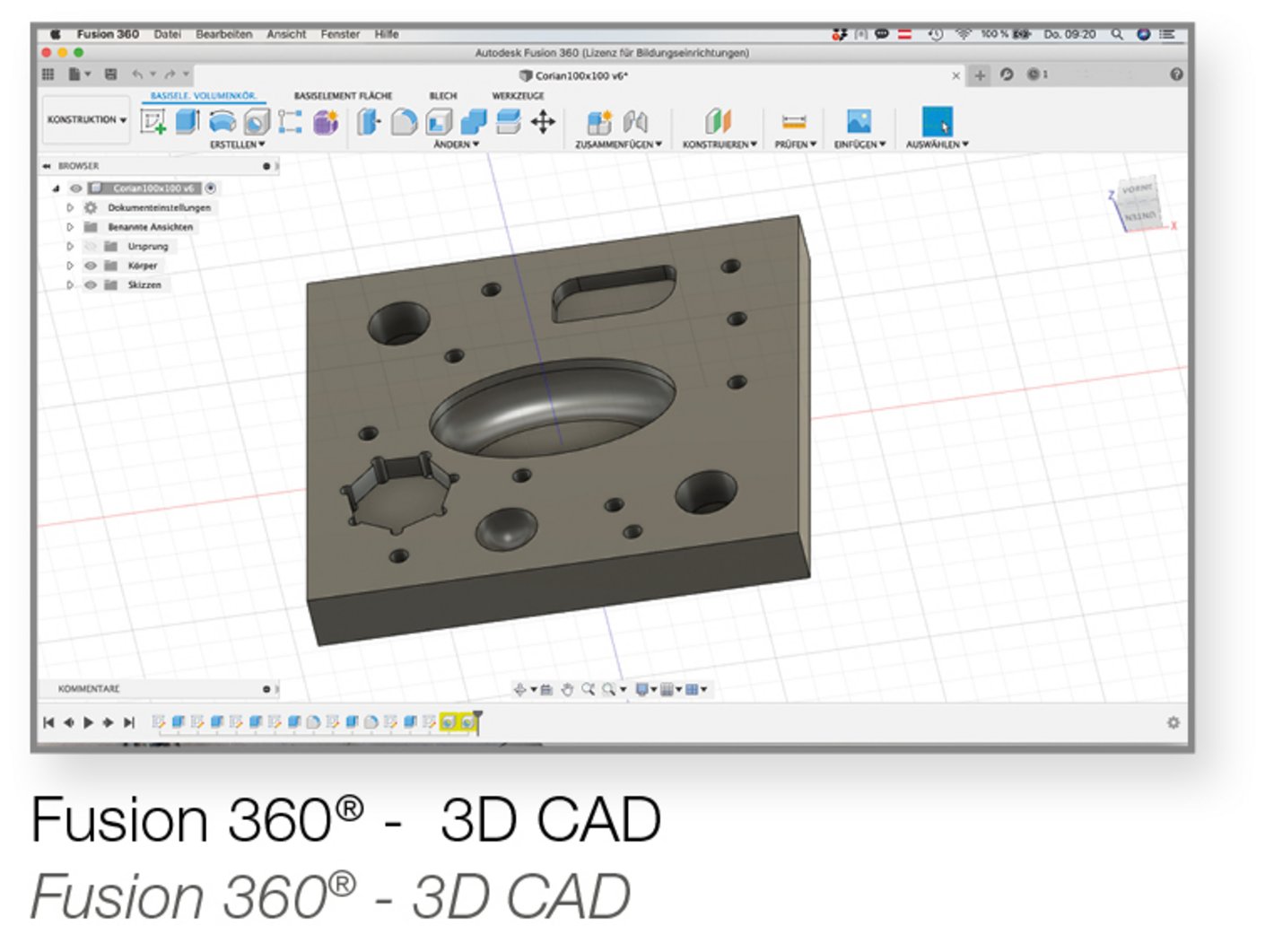

The computer-aided production of a model begins with its design on a computer. There are countless CAD programs (Computer-Aided Design) available on the market for this purpose.

In the next step, this design is imported into a CAM program (Computer-Aided Manufacturing). After entering the machining parameters, the CAM software calculates the tool paths. These tool paths, along with additional control commands, are then exported as G-code (a standardised machine control language).

Most CAM programs can generate machine code compliant with the RS-274 standard (DIN 66025). For simple geometries, the G-code can also be written manually.

In the third and final step, the G-code is loaded into the CNC control software (Computerized Numerical Control). The software reads the commands line by line and translates them into control signals for the stepper motors. The machine then moves according to the instructions, and the workpiece is machined accordingly.

🛠️ Overview: CAD / CAM / CNC Workflow

1) CAD / CAM Software (e.g., Fusion 360)

- CAD (Computer-Aided Design)

Used to design the model or part. The CAD process is fully independent of the actual production or the type of machine being used. - CAM (Computer-Aided Manufacturing)

Defines how the part will be manufactured and which machining strategies will be used. The CAM process is mostly independent of specific machine types, as the same part can often be produced on many different machines from different manufacturers. - Postprocessing

Before exporting the G-code, the postprocessor determines which CNC controller or CNC control software will interpret and execute the generated code.

ISO standard G-Code files (RS-274, DIN 66025) with extension .ngc can be loaded.

See explanation in reading sample CNC Handbook page 5.

2D and 2½D (Layer Milling):

For simple graphics and designs, free software like Inkscape can be used (see sample page 10 of the manual).

3D:

For 3D designs and solid models, CAD and CAM applications such as Autodesk Fusion 360 or DeskProto can be used. See the tutorial on postprocessors for Fusion 360.

(If you are using other CAM programs, check whether they include a postprocessor for LinuxCNC.)

Manual programming of toolpaths is also possible using any text editor.

- For simple 3-axis CNC milling projects

A very easy way to create G-code is by using Inkscape.

In the machine manual (included in print and as a PDF on the TCTControl software), you will find a sample project that shows step by step how to create both the drawing and the corresponding G-code file. - For more complex projects

We recommend using Fusion 360.

A short guide as well as the required postprocessors for our CNC system can be found here:

👉 Postprocessors and Tutorials for Fusion 360

We recommend Fusion 360, as the manufacturer provides a dedicated postprocessor for our machines.

👉 Fusion 360 Postprocessors & Tutorials

Of course, you can use any CAD/CAM system that outputs standard G-code (RS274NGC / DIN 66025).

Alternative: Inkscape (basic CAD/CAM)

For simple 3-axis CNC milling projects, a very easy way to create G-code is with Inkscape.

In the machine manual (supplied both in print and as a PDF on the TCTControl), you will find a sample project showing step by step how to create the drawing and generate the G-code file.

👉 Inkscape Sample Project

Important note for Linux users

If you want to use a PC or laptop with Linux, please avoid hardware with AMD graphics.

- Linux and AMD graphics are often incompatible or unstable.

- An AMD processor without integrated graphics (paired with an NVIDIA graphics card) works fine.

Yes. You can find sample projects and files in several places:

- Machine Manual [TVET-CNC-2]

Includes 9 projects on the following pages:

pp. 18, 19, 20, 21, 35–36, 37–38, 51, 67, 85 - Software Manual [TVET-CNC-1]

Includes 9 sample projects:- pp. 19–20

- pp. 24–26

- pp. 47–51 (Exercises 1–5)

- pp. 52–53 (engraving cylinders with 3-axis control, no 4-axis CAM required)

- pp. 54–70 (Inkscape sample project)

- TCTControl

The TCTControl software includes not only the exercise G-code files but also additional files.

You can access them via:

Open file from machine … → /examples/ and /examples/Uni-…/ - Website: thecooltool.com

Provides tutorials with sample projects for Fusion 360.

What are these projects for?

These numerous examples are intended to give you the knowledge and practical experience you need to develop your own projects and solve real problems.

For example:

- Manufacture spare parts:

A defective axle of a model car → measure the original part → create a drawing → generate the G-code to manufacture the replacement. - Create custom keychains:

Use Inkscape or Fusion 360 to design your own shapes and engravings.

You will need adminstration rights

Linux (Ubuntu etc): Verbindung via USB oder Ethernet. (Wi-Fi optional möglich).

OSX: Verbindung via Ethernet (Wi-Fi optional möglich). USB nur mit älteren OSX Versionen.

Der FAT-Bereich mit der Client sowie der Dokumentation wird unter allen OS gemountet (auch unter den aktuellen OSX Versionen).

For Windows 8 and higher the recommended solution is to install the “Remote NDIS Compatible Device” driver for the unknown device that appears in the Device Manager after connecting the TCTControl.

👉 Video instructions: Driver Installation Guide

Notes for Windows 10 and 11

During installation, you may receive an error message at the end of the process.

- If this happens, simply try to start a machine configuration.

- If the machine configuration loads correctly, the “Remote NDIS Compatible Device” driver has been installed successfully.

Yes, for TCTControl we do offer an emergency stop and relay module, that also allows for switching the Unimat CNC standard motor on and off from software.

See accessory 164425CNC E-stop/Relay module.

Yes, for the CNC 3 and 4-axis mill there is a speed controlled spindle motor available.

See accessory Milling and Engraving Spindle 164420CNC.

Yes there is an enclosure available that is suitable for the UNIMAT CNC or UNIMAT Laser. More information you can find here:

Please contact us! We shall be happy to send the download link for the latest version of the client for 32-bit.

TCTControl: Perform an online-update. In case the update aborts, just restart it until it finishes - all files will be restored.

SandyBox: Please contact us (online update is not available).

For USB connection: Please make sure the supplied driver has been installed successfully (see question about driver installation).

For LAN connection: Has the IP address of the controller been set correctly (default 192.168.0.3)

Is there a tool defined for the lathe?

Yes. Currently, the two turning tools that are predefined in Fusion 360 are also included in the standard tool table for the lathe.

If they are missing in your installation, you can download the latest tool table via the online update.

Do I need to use a tool table when working on the lathe?

Many users write G-code for simple turned parts directly in a text editor and often work without a tool table. For more complex parts, however, defining tools in the CAM software is strongly recommended.

How are tools defined in CAM software?

In CAM systems such as Fusion 360, you can (and must) define the tools to be used in the software’s tool table. These tools are not bound to a specific machine but are selected per project for manufacturing purposes.

How are tool tables handled on the machine?

On the control side, each machine can have its own tool table — for example, one for milling and another for turning. These machine tool tables do not automatically synchronize with the CAM tool tables (with some exceptions in purely industrial systems).

Therefore, it is essential to check:

- whether the required tool is present in the machine’s tool table, and

- whether it has the correct tool number assigned.

How is the shape of a turning tool defined in the tool table?

Details on defining turning tool geometry can be found here:

👉 LinuxCNC Lathe Documentation

No. CNC milling and turning is not a simple drag-and-drop process like 3D printing or laser engraving. CNC machining is much more complex, as many factors must be considered — such as:

- tool type and diameter

- dimensions and shape of the raw material

- material properties

- machining strategy (optimized for quality, speed, or both)

Most CAM software can import formats like .STEP, .STL, .IGES, etc. However, these files cannot be transferred directly into the CNC control software. Instead, they must first be processed in the CAM software, where toolpaths are generated and then exported as G-code for the CNC machine.

You have two options:

- Via USB cable (standard connection)

- Via LAN cable through your network

Standard Ethernet Configuration

The default LAN settings are:

allow-hotplug eth0 iface eth0 inet static address 192.168.60.3 netmask 255.255.255.0 gateway 192.168.60.1 dns-nameserver 192.168.60.8 dns-nameserver 192.168.60.1

How to Change the Network Configuration

- Start terminal.bat

(located under TCTCONTROL\Windows\TOOLS\) - Navigate to /etc/network/

Create a backup of the configuration file:

sudo cp interfaces interfaces_original

Open the file for editing:

sudo vi interfaces

- Adjust the parameters of “The primary network interface” to match your network.

- Save the file and reboot the TCTControl (BeagleBone Black).

Step 1: Check the network connection between your PC and the TCTControl.

Start the terminal.bat file (located under TCTCONTROL\Windows\TOOLS\).

- Case A: The terminal opens, and you can access the TCTControl → the network connection is working.

- Case B: The terminal does not open → no network connection is available.

Step 2: If the network connection works (Case A):

- Run the online_update.bat file (also under TCTCONTROL\Windows\TOOLS\).

- If the update completes successfully, reboot the TCTControl.

- Run the online update again.

- Once all components are up to date, start the machinekit-client.

→ You should now be able to access the machine configuration selection.

Step 3: If there is no network connection (Case B):

Install (or reinstall) the required driver for the TCTControl.

What is EMC2?

EMC2 (now known as LinuxCNC) is a G-code interpreter. It converts G-code according to the RS274NGC standard into signals for the stepper motors.

👉 Reference: LinuxCNC G-code documentation

How does this relate to Fanuc?

- Fanuc is not a true universal standard, but since it is one of the most widely used CNC systems worldwide, it has become a de facto standard.

- RS274NGC (used by EMC2/LinuxCNC) is very similar to Fanuc. Only a few uncommon or exotic G-codes differ.

- As a result, G-code written for Fanuc can often also be used with EMC2, and vice versa.

What about UNIMAT CNC machines?

Our UNIMAT CNC machines are designed to be simple and do not include advanced functions such as automatic tool changers.

- Therefore, the G-code commands they use are largely compatible between Fanuc and EMC2/LinuxCNC.

- In practice, this means G-code created for Fanuc usually runs on EMC2 without modification.

- On the TCTControl, all required configurations for our CNC machines are already included.

The TVET-CNC-1 manual explains everything you need to start and operate our CNC machines. - If you want to create your own configuration, you will find detailed information here:

👉 Machinekit Project - Sometimes, the LinuxCNC documentation is also helpful, since Machinekit is an “offshoot” or new development of LinuxCNC:

👉 LinuxCNC Documentation - For small modifications (e.g., adding an Emergency Stop to the UniTurn configuration), the best approach is to look at an existing UNIMAT CNC configuration that already includes an E-Stop (check the .ini and .hal files). This will show you what adjustments are necessary.

Questions and answers for TCT-Control

Installing the “NDIS Compatible Remote Device” Driver via Device Manager (Windows)

⚠️ Note: Administrator rights are required!

Step-by-Step Instructions:

- Open Device Manager.

- Connect the TCTControl:

- Plug the TCTControl into the provided power supply.

- Connect it to your PC via the included USB cable.

- Wait approximately 30–60 seconds.

- An unknown (USB) device will appear in Device Manager.

- Update the driver for this device:

- Select “Update Driver”

- Choose “NDIS-compatible remote device” as the driver.

🎥 Need help?

Watch the detailed installation video here:

👉 https://vimeo.com/454312842

⚠️ Important Note:

If you receive a warning message after installation stating that this may not be the correct driver for the device — ignore the message and proceed.

✅ Final Step: Start the Machinekit Client

Run the following file on your PC:

TCTCONTROL\Windows\Start_machinekit-client.bat

If you are shown a selection of CNC machine configurations, the installation was successful.

TCTCONTROL\Windows\TOOLS\files.bat

This is a file transfer utility that provides access to the Linux-based operating system on the TCTControl unit.

It can be used to copy files (e.g., G-code files) stored on the TCTControl to your PC.

Login Information

- Linux OS on TCTControl

- User: machinekit

- Password: machinekit

- The same password applies when prompted by the file transfer tool:

- PASSWORD: machinekit

192.168.7.2

(The IP-Adress of the USB-Networkconnection cannot be changed)

192.168.60.3

(The IP-Address of the LAN network connection can be adjusted to integrate kann angepasst werden um den TCTControl mit einem bestehenden Netzwerk zu verbinden.

/etc/network/interfaces

(Kontaktieren Sie Ihren Systemadministrator.)

The Linux real-time operating system runs on a BeagleBone Black, and the entire CNC control software – Machinekit – is pre-installed.

No Linux knowledge is required to use the TCTControl.

Major software upgrades (as well as improper modifications to the Linux operating system) may require reflashing the TCTControl (BeagleBone Black).

Please follow the tutorial video: https://vimeo.com/518159161