UNIMAT CNC

Computer-Controlled Manufacturing for Schools & Training

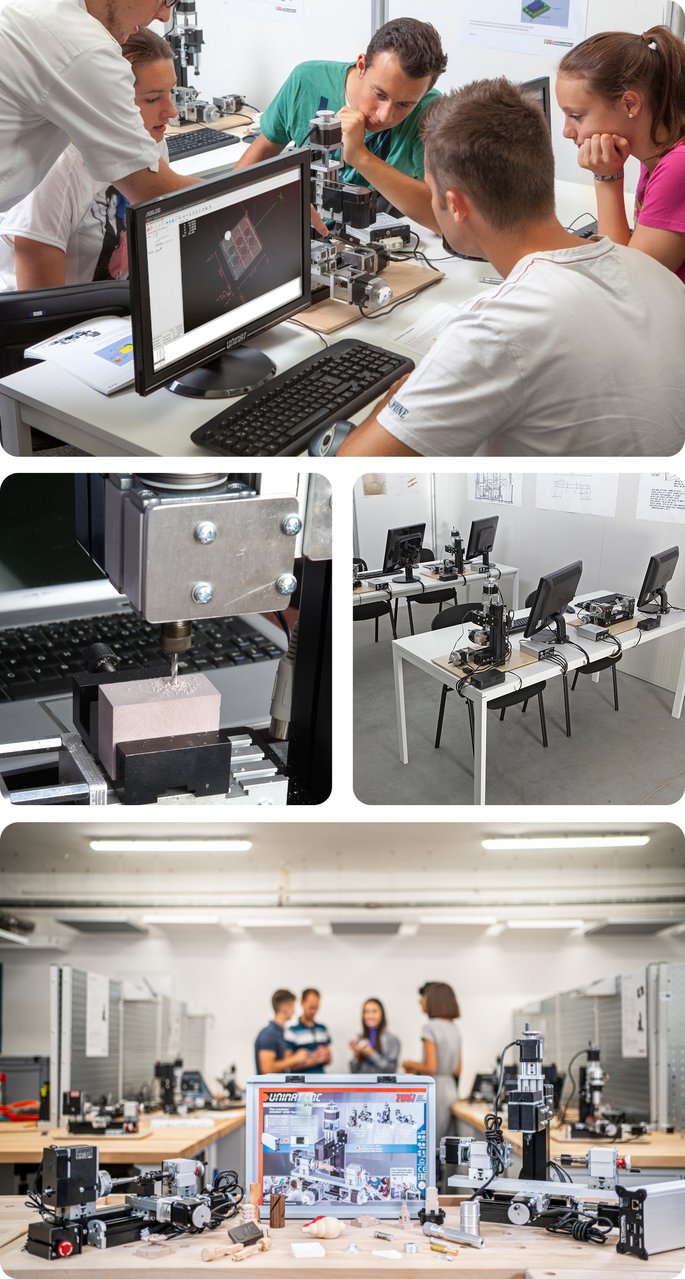

Teaching CNC Technology through Hands-On Practice

The UNIMAT CNC system is specifically designed for use in secondary education and technical training – ideal for technical schools, vocational training centers, and apprenticeship programs.

It allows learners from around age 14 to independently complete the entire CNC manufacturing process – from CAD design and CAM implementation to real machining on the device.

The modularity of the UNIMAT system continues into the CNC sector: the system supports a wide variety of configurations – from milling centers to computer-controlled lathes. This enables the setup of a complete CNC machine park with minimal budget and space requirements.

⚙️ Technical Features & Capabilities

The CNC machines are based on proven components from the MetalLine series and are equipped with 2-amp stepper motors that provide precise and reliable axis control.

Typical machine modules include:

• CNC lathe

• Vertical milling machine

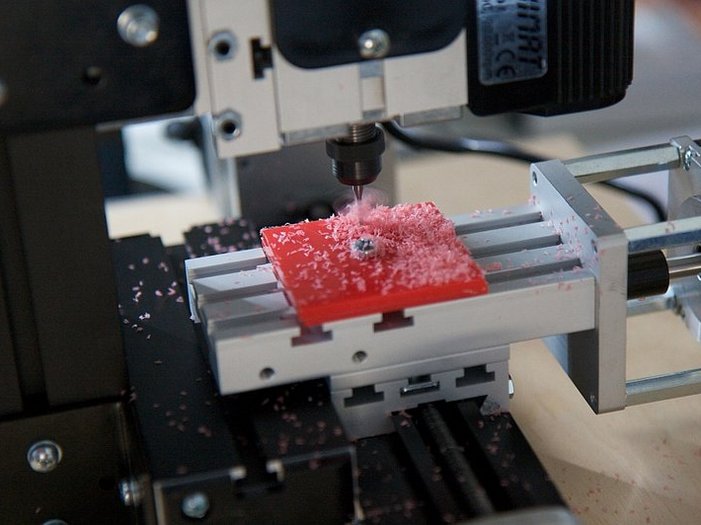

• Surface milling machine

• Cross slide (travel 50 mm, expandable)

• Longitudinal slide (travel 145 mm, expandable)

The systems achieve repeat accuracy of up to 0.07 mm. Depending on configuration, up to 4 axes can be controlled simultaneously – an ideal introduction to the world of professional CNC machining.

💻 Software-Based Control – Machinekit

Control is provided via the open-source CNC software Machinekit, pre-installed on the included TCTCONT4 controller. The hardware platform is a Beaglebone Black, which can be easily integrated into existing networks.

- Simulation and control of CNC processes through a graphical user interface

Insight into G-code promotes understanding of automated workflows

Dedicated post-processors and quick-start guides are available for Fusion 360, enabling a hands-on and intuitive teaching of the full CAD-CAM-CNC workflow.

🧰 Didactic Value

The UNIMAT CNC system was developed not just as a classroom project tool, but as a fully didactic platform for teaching:

- technical understanding of control systems

- practical skills in computer-aided manufacturing

- interconnected thinking across the complete CAD-CAM production process

By allowing students to actively operate machines instead of relying on theoretical simulations or inaccessible industrial equipment, it offers genuine hands-on learning.

The UNIMAT CNC system combines modular mechanical engineering with modern control technology.

It provides a cost-effective, practice-oriented, and technically advanced solution for computer-aided training – ideal for technical high schools, vocational colleges, and training centers.

Discover our CNC machines

CNC Solutions for Every Level of Technical Education

Whether you're introducing students to basic metalworking or guiding them through advanced CNC projects, we offer the right machines and systems for every stage of training. From manually operated turning modules to fully functional 4-axis CNC milling machines, our solutions cover a wide range of applications.

Ideal for schools, training centers, and technical labs that value hands-on, modular, and safe technology. With well-designed accessories, software, and didactic teaching materials, we make technical learning tangible and future-oriented.

No matter the level – we have the right CNC machines for every area of technical education.

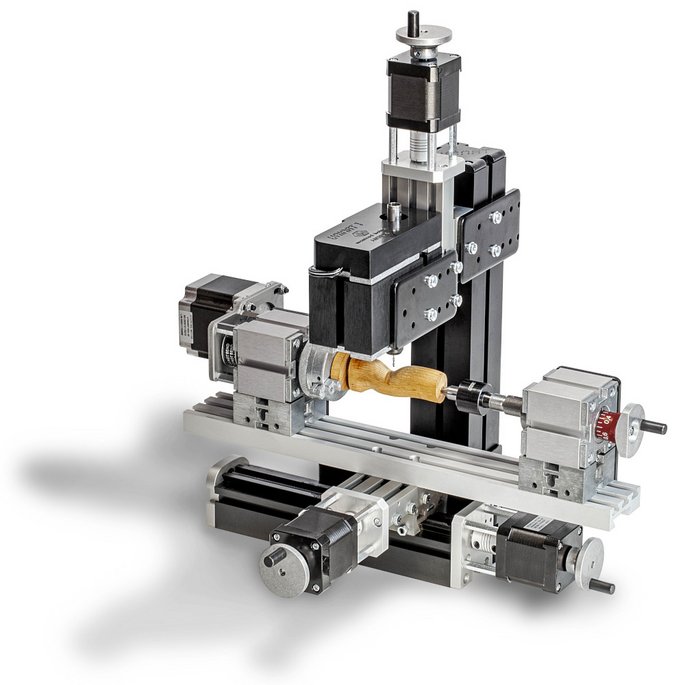

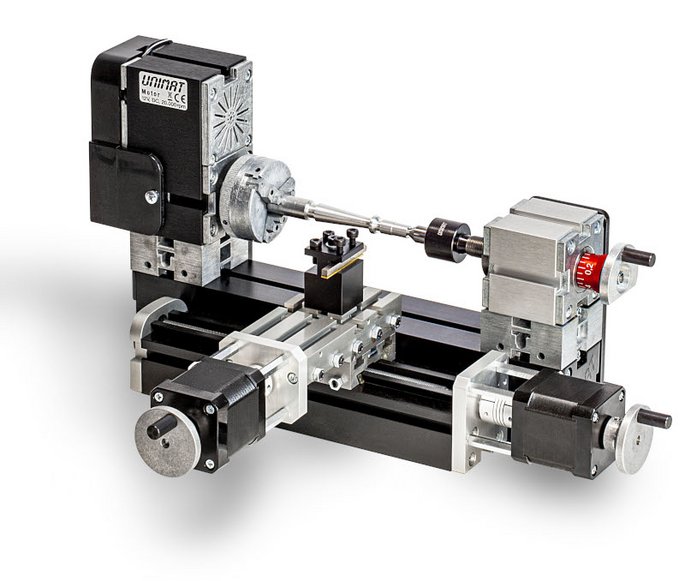

UNIMAT CNC Lathe

UNI-DREH

3-Jaw-Chuck, precision live center, tool post and turning tool.

Machinable materials: wood, acrylics, wax, non-ferrous and soft metals.

| Drive | Steppers, 2 A, 1.8° | |

| Nubmer of CNC axes | 2 | |

| Max. positioning speed | 300 mm/min | |

| Head spindle | 4000 U/min | |

| Travel X/Z | 50 mm/145 mm (expandable) | |

| Accuracy | 0.05 mm | |

| 3-Jaw-Chuck | Clamping capacity 1.8 - 56 mm inside, 12 - 65 mm outside |

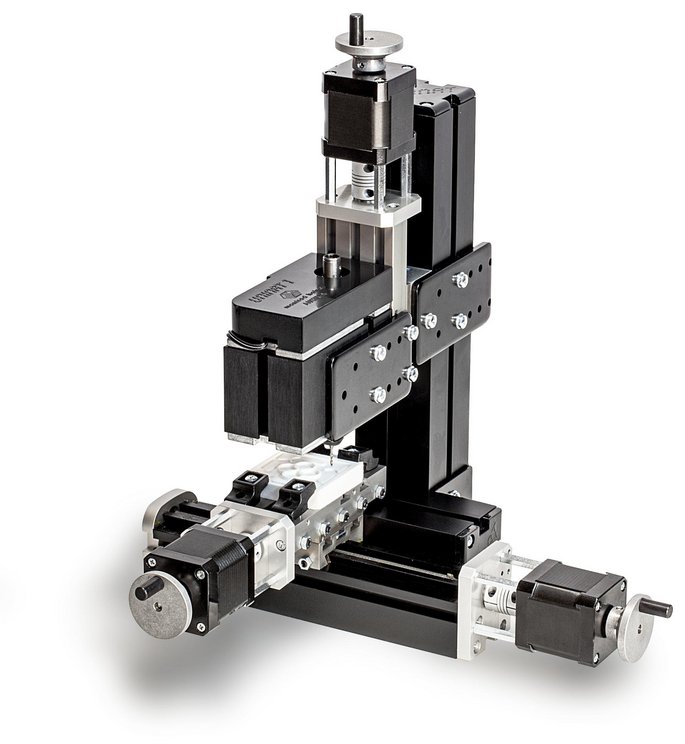

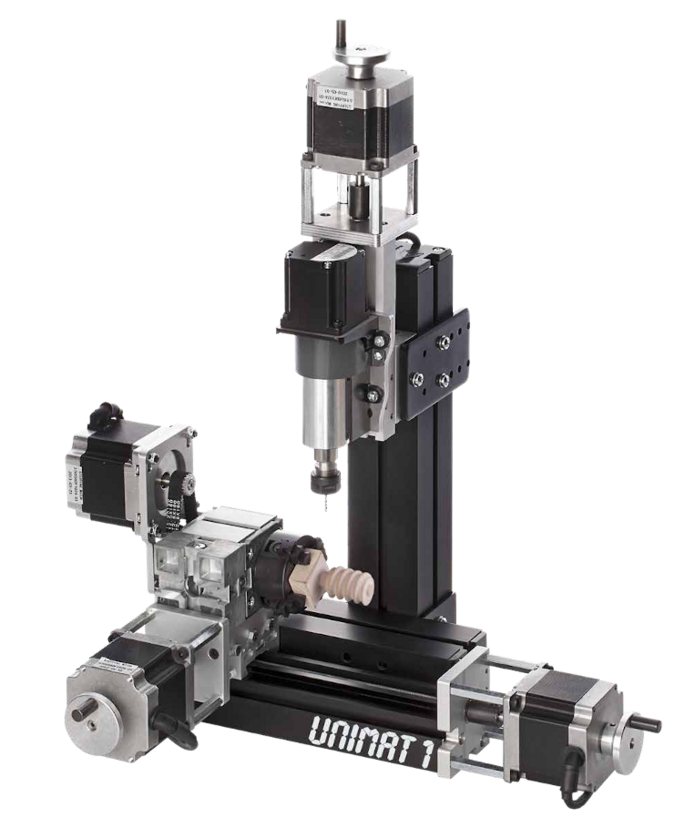

Vertical mill UNI-FRAES3EXT

Same as UNI-FRAES3 but 80mm, Y-, Z-travel and controlled milling spindle (164420 CNC)

Technical Data:

| Number of CNC axes | 3 |

| Drive | Steppers, 2 A, 1,8° |

| Max. Positioning speed | 300 mm/min |

| Travels Z/Y | 80 mm / 80 mm |

| Travel X-axis | 145 mm (expandable) |

| Increment rotation axis | (360°/3200)*0,5 = 0,05625° |

| Accuracy | 0,07 mm |

| Speed of head spindle up to | 15 000 rpm, with 1/8" collet |

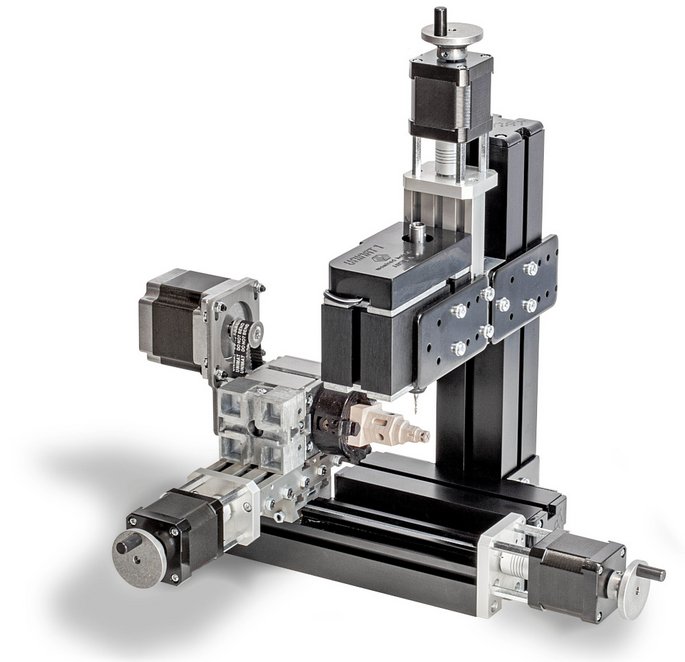

UNIMAT CNC 4-axis mill with controlable spindle

UNI-FRAES4-SC

Same as UNI-FRAES4 but with controlled milling spindle (164420 CNC)

Technical Data:

| Number of CNC axes | 4 |

| Drive | Steppers, 2 A, 1,8° |

| Max. Positioning speed | 300 mm/min |

| Travels Z-axis | 80 mm |

| Travel Y-axis | 50 mm |

| Travel X-axis | 145 mm (expandable) |

| Increment rotation axis | (360°/3200)*0,5 = 0,05625° |

| Accuracy | 0,07 mm |

| Speed of head spindle up to | 15 000 rpm, with 1/8" collet |

Required for controlling the UNIMAT CNC machines

The pre-installed software allows for loading, manipulating and processing of ISO standard g-code files (RS-274). It also offers an editable tool table and tool path simulation. In addition to the manual also a training book for introduction to CNC and g-code programming is included.

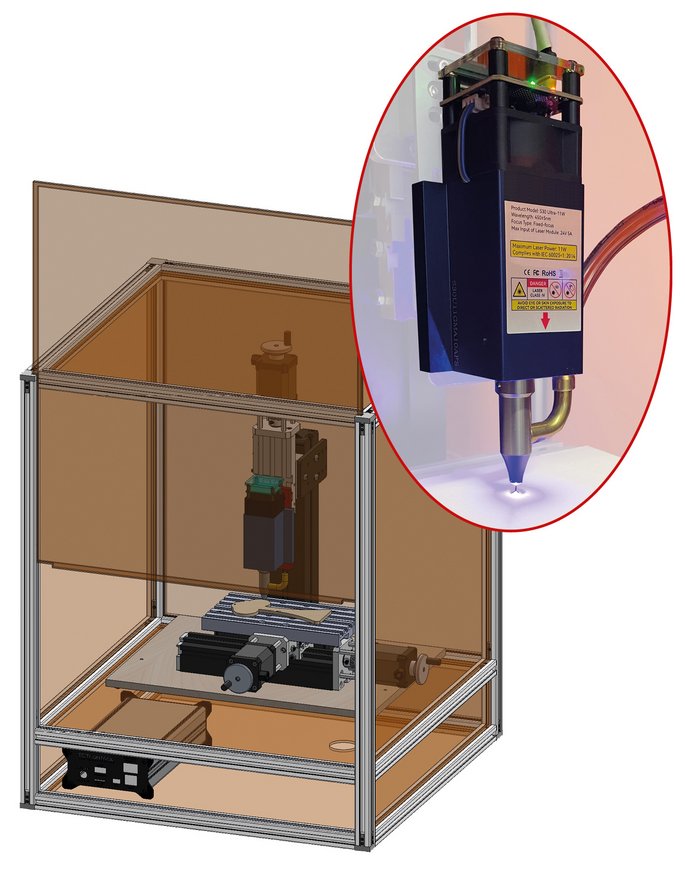

Laser-Module CNC with safety enclosure

Article: UNI-Laser-S

The laser is compatible with all variants of the UNIMAT CNC vertical milling machines (3- and 4 axes)

Laser Power: 11 W

Wavelength: 450nm

Focus type: fixed focus

Input: 24V/ 5A

Machinable materials:

| Cutting | Engraving |

|---|---|

| wood cloth acrylic various plastic carton | wood stainless steel leather acrylic ceramics various plastic carton anodized aluminium |

More configurations

UNIMAT CNC Hot Wire Cutter

UNI-CUT-3D

| Number of CNC axes | 3 |

| Drive | Steppers, 2 A, 1,8° |

| Max. positioning speed | 300 mm/min |

| Travel X/Y | 240 mm/145 mm |

| Size Rotary Table | ø 260 mm |

| Increment Rotary Table | (360°/3200)*0.5 = 0.05625° |

| Cutting bow | width 170 mm, height 350 mm |

| Cutting transformator | continuously adjustable, 600 - 850° Celsius |

| Accuracy | 0.1 mm |

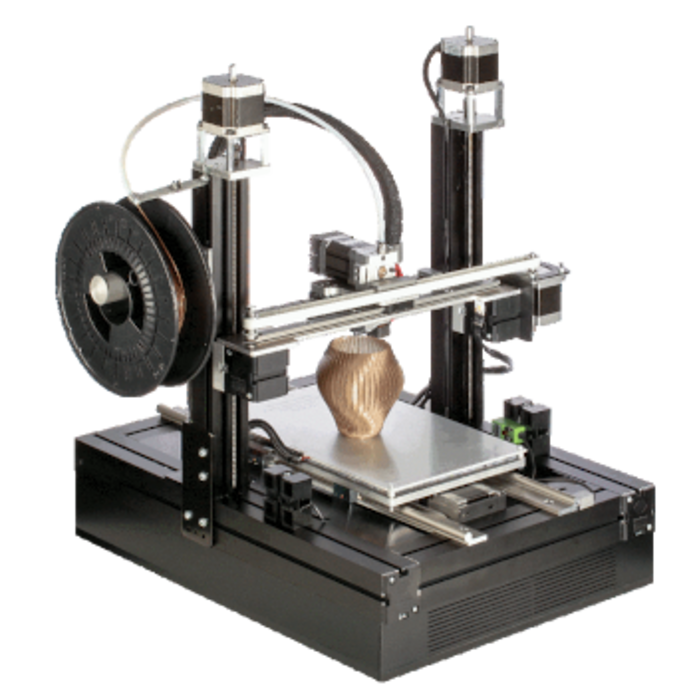

Unimat 3D-Printer

UNI-PRINT-3D

• Filament quick change, low maintenance, adjustable guideways

• Full metal frame and sturdy construction

• For all common filaments: PLA, ABS, Nylon, Laybrick etc.

• Open Source Software: Machinekit & cross platform user interface for Windows, OSX, Linux, Android

Curriculum example

Curriculum secondary level II specialized grammar school, engineering, Schleswig Hollstein, Germany. pp. 33:

"Knowledge about automated production facilities …planning and processing of selected components ... the emphases must be on automation of production processes as well as on the CAD-CAM combination and quality management. … Processing of parts should be executed automated and students should be integrated in the process chain.”